Are the Features and Capabilities of eFuses Worth the Added Complexity? Ask Automotive Designers

The basic thermally activated fusible link—better known as a fuse—has been with us since the earliest days of electricity and electrical power. A fuse does one thing and does it well: it goes from a near-perfect current conductor to a near-ideal open circuit over a period from a few milliseconds to several seconds (depending on the model) when there is excessive current and resultant heat to melt its element.

Once a fuse is selected, installing and using it is a straightforward exercise as there are no connection options, initialization steps, or configuration settings. It’s just a two-terminal device that provides critical circuit protection while enabling a design to more easily meet many regulatory and safety mandates.

Fuses are available in countless physical configurations and current ratings, with some more common than others. Among the more common fuse styles are the 3AG glass fuse (1/4 inch (in.) diameter, 1¼ inches long) which is often used in smaller commercial and industrial products, as well as some line-operated consumer products, and the blade fuse which is widely used in automotive applications (Figure 1).

Figure 1: The 3AG fuse style was one of the first mass-market fuse styles and is still used (left); the automotive industry eventually went to thinner blade-style fuse bodies (right). (Image source: Littelfuse, Inc.)

Figure 1: The 3AG fuse style was one of the first mass-market fuse styles and is still used (left); the automotive industry eventually went to thinner blade-style fuse bodies (right). (Image source: Littelfuse, Inc.)

Ironically, the 3AG designation is short for “Size 3 Automotive Glass” and was originally designed in the 1930s for automobiles. However, as the number of fuses in a vehicle increased, the automotive industry migrated away from the 3AG and developed blade fuses.

Despite its many positive attributes and unparalleled success, as proven by the millions (or is it billions?) of these fuses used every year, times and design needs do change. In recent years, the electronic fuse (usually written as eFuse or e-Fuse) has become a widely used alternative—or a supplement to—the thermal fuse. Some designs use both, with eFuses for localized circuit protection and thermal fuses for system-level protection.

Among the key features of the basic eFuse is its quick response time of milliseconds or less, but its attributes don’t end there. While many eFuses initially targeted subcircuit protection such as hot-swap applications, some eFuses were soon certified to the appropriate UL and IEC standards, thus allowing them to be approved for safety-related protection.

eFuses going beyond basic current cutoff

As eFuses are silicon-based solid-state devices, they soon followed the path of other basic ICs by adding additional features and functionality. These include user-programmable current thresholds, latching output, optional automatic retry, power-good signal, current-level monitoring, reverse-current blocking, and thermal shutdown.

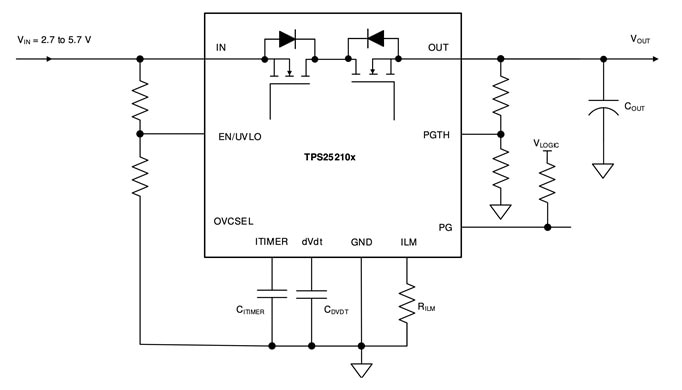

For example, the Texas Instruments TPS25210ARPWR is a 2.7 to 5.7 volt, 4 ampere (A), 31 milliohm (mΩ) eFuse with a response time of 500 nanosecond (ns) (typical) (Figure 2). The user can set the current limit from 0.5 A to 4.44 A via an external current-sense resistor.

The TPS25210ARPWR is a basic eFuse for moderate current levels; it includes some useful features beyond basic cutoff of current when its threshold is exceeded. (Image source: Texas Instruments)

The TPS25210ARPWR is a basic eFuse for moderate current levels; it includes some useful features beyond basic cutoff of current when its threshold is exceeded. (Image source: Texas Instruments)

In addition to basic fusing, this eFuse protects against overloads, short circuits, voltage surges, reverse polarity, and excessive inrush current. For applications with specific inrush current requirements, designers can set the output slew rate with a single external capacitor. Loads are protected from input overvoltage conditions by clamping the output to a safe, fixed, pin-selectable maximum voltage.

eFuses such as this offer a long list of features and have made the otherwise “dumb” fusing function smarter, more flexible, and more informative and useful to the system it is charged with protecting. This is in sharp contrast to the conventional thermal fuse with its fixed current rating.

Not your basic eFuse

The limited functionality and lack of I/O connectivity of the fusible link are at odds with the needs of today’s smart, networked vehicles. In contrast, the many capabilities of eFuses make them especially attractive for automotive applications. For this reason, the industry has developed eFuses that meet stringent automotive qualifications and incorporate many desired additional capabilities.

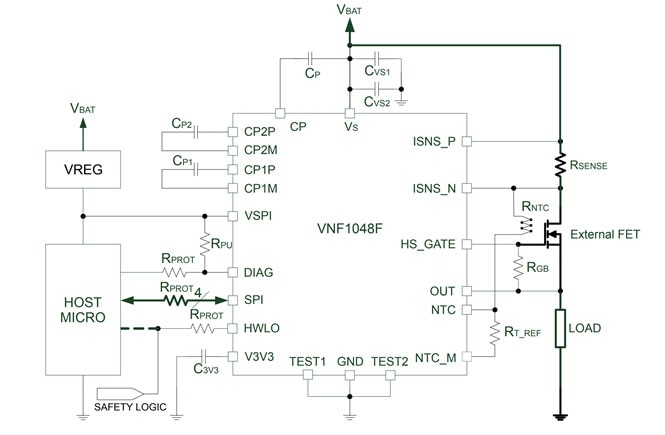

One example is the recently introduced VNF1048F from STMicroelectronics, an AEC-Q100-qualified, high-side switch controller intended for automotive power distribution applications. It combines enhanced system protection and diagnostic features with STMicroelectronics’ “I2-t” silicon-fuse technology (Figure 3).

Figure 3: The AEC-Q100 qualified VNF1048F is an eFuse, but it also includes a high-side switch controller along with many other features and connectivity options. (Image source: STMicroelectronics)

Figure 3: The AEC-Q100 qualified VNF1048F is an eFuse, but it also includes a high-side switch controller along with many other features and connectivity options. (Image source: STMicroelectronics)

Compatible with 12, 24, and 48 volt automotive power subsystems, the VNF1048F’s flexibility makes it a good fit for the latest automotive “zonal” electronic/electrical architectures that boost efficiency and reliability, while also supporting increased electrification and extra functions for smart driving.

The I2-t feature provides fast-acting, resettable, and reliable over-current protection. Silicon fuses also help simplify vehicle wiring harnesses and reduce weight by eliminating user-accessible fuse boxes and the associated cabling.

The feature-laden and adaptable VNF1048F has a 32-bit serial peripheral interface (SPI) which is compatible with 3.3 volt and 5 volt CMOS logic levels, allowing a host microcontroller to configure and monitor system protection and diagnostic features. These features include under-voltage and over-temperature protection, a two-stage charge pump for external MOSFET drive, plus MOSFET thermal protection, desaturation shutdown, and I2-t fuse settings.

High-precision digital current sensing is built-in using an external high-side shunt resistor. The device also integrates analog-to-digital converters (ADCs) for monitoring the temperature-sensing thermistor voltage (VNTC), output voltage (VOUT), and MOSFET drain-source voltage (VDS).

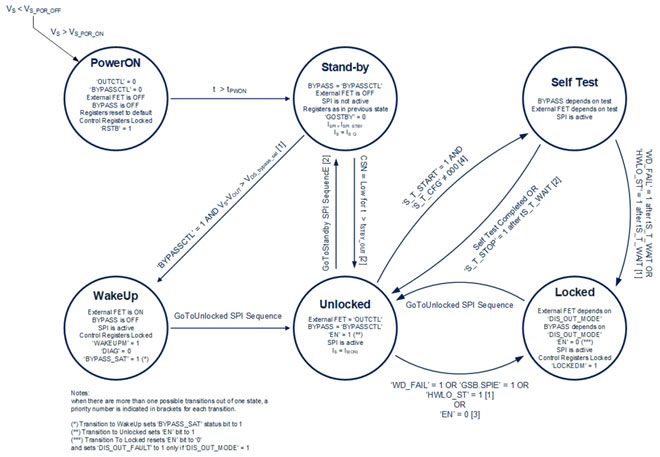

A full-featured and highly functional smart controller such as the VNF1048F provides more than just integration of somewhat-related functions. It also embeds a sophisticated state machine that manages and assures that its performance, actions, and reactions mesh with the needs of the system it is monitoring (Figure 4).

Figure 4: The state diagram for the VNF1048F operation and sequencing clearly demonstrates how and why it is much more than just a basic eFuse. (Image source: STMicroelectronics)

Figure 4: The state diagram for the VNF1048F operation and sequencing clearly demonstrates how and why it is much more than just a basic eFuse. (Image source: STMicroelectronics)

Commensurate with its high level of functionality and integration, the VNF1048F is documented in a 52-page datasheet. Anyone planning to use this device had better be ready to do some serious studying of the many modes, functions, initializations, and settings this device supports; there’s lots of homework to do before applying it.

This last point hints at possible concerns when using such sophisticated components. One of the virtues of the plain, old-fashioned thermal fuse is that once you select the appropriate device, it requires almost no further design effort. You simply put the fuse in the circuit, and that’s it: no functions to initialize, no parameters to set, no protocol decisions to make, no downloading via a link. In contrast, advanced eFuses demand more design-in time and effort, as well as debugging allowance.

Conclusion

It's part of the eternal engineering design dilemma: do you keep it simple and accept limited flexibility, or do you commit to a more advanced component, knowing it will require more work to implement? In the case of eFuses, and thanks in large part to the increasing complexity and flexibility requirements of automotive designs, it appears that the pain is well worth the gain.

Related Content

“Get Comfortable with eFuses: They Have Many Useful Features”

https://www.digikey.com/en/blog/get-comfortable-with-efuses-they-have-many-useful-features

“Why and How to Effectively Use Electronic Fuses to Protect Sensitive Circuits”

https://www.digikey.com/en/articles/why-and-how-to-effectively-use-electronic-fuses

“How to Use eFuses to Design Compact Short Circuit, Overvoltage, and Thermal Protection Solutions”

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum